When Curves Meet Reality: Solving Core Challenges in Multi-Curved Aluminum Panel Design and Installation

Have you ever been excited by a stunning architectural rendering, only to be exhausted by the complexities of multi-curved aluminum panels during construction? Have you faced the frustration of panels that won't close properly on-site, or seen harsh light disrupt the smooth, flowing curves of the final facade?

In today's pursuit of extreme architectural forms, multi-curved aluminum panels (especially double-curved panels) have become key to creating iconic building facades. However, the hidden challenges across the entire chain—from design and fabrication to installation—often lead to runaway costs, delayed schedules, and a final result that falls short of the vision.

Based on our experience collaborating on dozens of high-end curtain wall projects globally, we find that 90% of the difficulties stem not from the material itself, but from the "gap between design and execution." Today, I want to share the three most critical pain points and their proven solutions.

Pain Point #1: The "Perfection" of the Digital Model vs. The "Tolerance" of Real-World Fabrication

The Problem: The perfect NURBS surfaces created by architects in Rhino or Grasshopper often suffer from precision loss during data conversion and due to fabrication limitations. This directly leads to panels that "don't fit" on-site, requiring expensive and time-consuming secondary cutting or adjustment in the field.

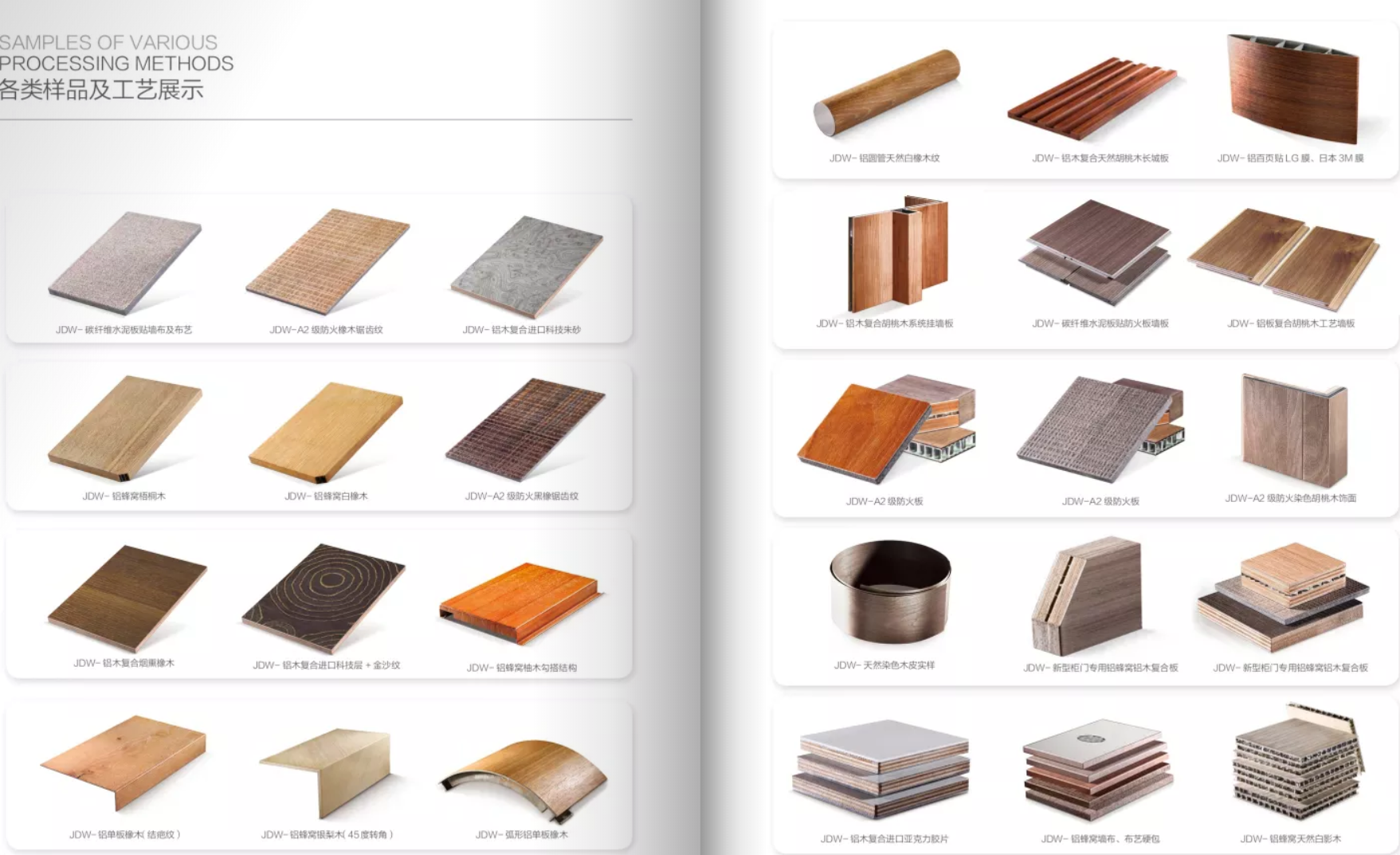

Our Approach: A Closed Loop from "Design for Manufacturability" to "Precision Fabrication"

We insist on introducing manufacturing thinking early in the detailed design phase. Our method is:

Manufacturability Analysis: Before data conversion, our engineers collaborate with your design team to evaluate the minimum radius of curvature and panelization rationality, ensuring the design is feasible within existing equipment and process capabilities.

Digital Assembly Simulation: Using specialized software, we perform a virtual pre-assembly of all panels to identify and eliminate potential clashes and interferences upfront, solving problems before they leave the factory.

Pain Point #2: On-Site Installation Becomes a Game of "Brawn" and "Luck"

The Problem: Traditional installation of multi-curved panels heavily relies on workers' experience and on-site "adjustment, hammering, and patching." This is not only inefficient (taking over three times longer than standard curtain walls) but also fails to guarantee the smoothness of the overall surface, leading to inconsistent final quality.

Our Approach: A "Prefabricated" Unitized Installation System

We innovatively transform complex curved surfaces into precision-fabricated "unitized panels" assembled off-site.

The Key is the Connector: Our proprietary "Three-Directional Fully Adjustable Mounting System" allows each panel up to ±15mm of adjustment in the X, Y, and Z axes. This means it can effectively absorb construction tolerances from the main structure and accumulated fabrication errors, making high-precision installation as controllable and efficient as "building with blocks."

The Tangible Result: This approach can increase on-site installation efficiency by over 40% and ensures a smooth, continuous final surface with uniform joints.

Pain Point #3: The "Black Box" of Cost Overruns – Reject Rates and Hidden Expenses

The Problem: While quotes for multi-curved panels may seem clear, hidden costs for molds, high reject rates (industry average 20%-25%), and unforeseen on-site modifications often blow the total project budget.

Our Approach: Transparent Cost Structure and Value Engineering

We are committed to opening this "black box":

Cost Reduction via Process Optimization: For non-standard double-curved shapes, we prioritize evaluating the feasibility of using mold-less processes like "multi-point forming" or "skin stretching" to reduce your upfront mold investment for a single project.

Accurate Budget Lock-in: During the quoting phase, we provide a detailed cost breakdown analysis, clearly separating material, process, risk, and profit, ensuring transparency for every dollar spent. Through upfront precision control, we have successfully kept the comprehensive reject rate below 8% for multiple projects.

Our Philosophy: We believe the best curtain wall solution is one that allows the architect's vision to be perfectly realized, gives the contractor clear and controllable work, and delivers true value for the investor's budget. This is not just about supplying panels, but about providing a complete technical service system—from digital design and precision manufacturing to efficient installation.

We specialize in providing one-stop solutions for complex curved facades for global high-end commercial complexes, transportation hubs, and cultural landmarks.

Engagement & Call to Action:

What was the biggest challenge in your recent multi-curved/double-curved project? Was it fabrication precision, installation coordination, or cost control? Share your experience or questions in the comments below.

If you are planning a challenging curved facade project and would like a preliminary technical feasibility and cost assessment, feel free to send me a private message. We can provide a reference solution based on our successful past cases.